Sign up now for the retail focus webinar replay and learn how to leverage data and visibility to turn the supply chain into a competitive advantage!

5 Key steps to implement a visibility solution for a freight forwarder

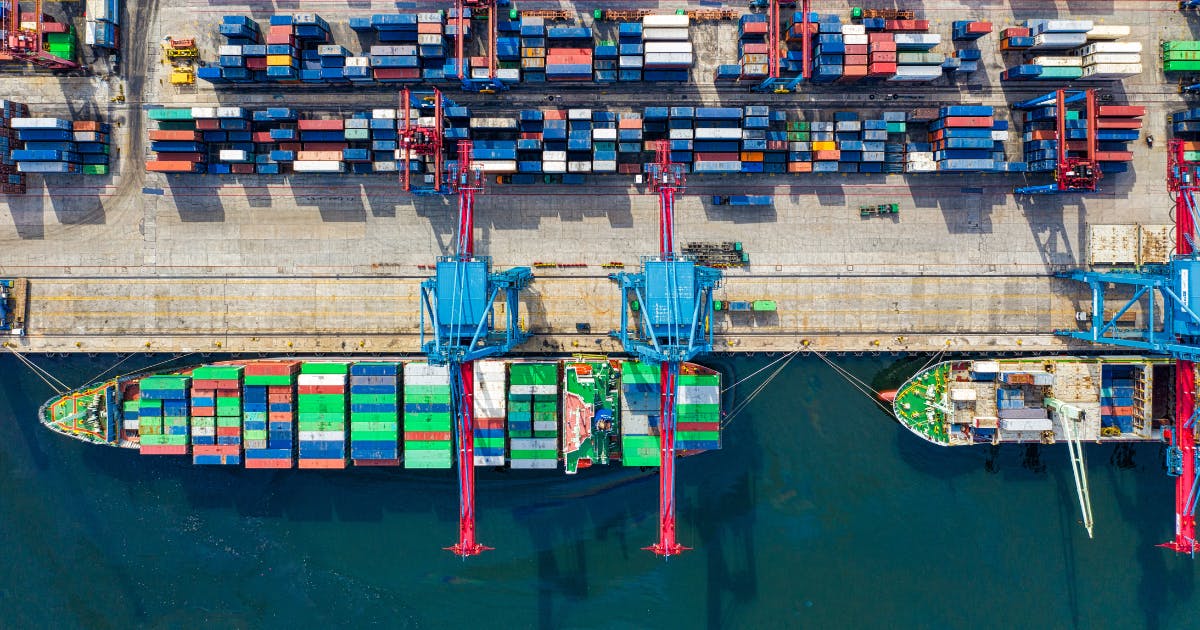

A visibility solution is crucial for freight forwarders to meet the growing expectations of their customers and to remain competitive in the digital era. It allows forwarders to provide real-time updates, optimize their operations, and enhance the overall customer experience.

With the ever-increasing demand for transparency and visibility in the supply chain, real-time tracking and monitoring capabilities are essential for freight forwarders to remain competitive. Below are the key steps to implement a visibility solution:

1. Scoping needs

The first stage is for freight forwarders to determine the project scope. They must identify the modes of transportation and coverage required for track and trace. For example, are the freights mainly by sea, air, road and/or rail, from port-to-port or airport-to-airport or door-to-door. Forwarders might also consider which routes require real-time tracking and which ones require capturing data for analysis and reporting purposes. For instance, for a relatively short haulage of just 20km from a port, a freight forwarder may not require real-time tracking. However, the freight forwarder might still want to capture certain information about the route, either through track and trace or declarative data, for reporting purposes, particularly for calculating the carbon footprint.

The scope also includes the feasibility of tracking different modes of transportation and the value it provides to customers. It is essential to understand the carriers used, their coverage, and the number of shipments per mode. It needs to consider the number of interfaces required for different systems, including inbound data feeds and potential pushback to the TMS for operational needs.

By determining the project scope, freight forwarders can develop a clear understanding of their requirements and prioritize deployment stages.

2. Reviewing IT maturity

Before implementing a visibility solution, freight forwarders will review their IT maturity level and assess their readiness to handle the influx of data generated by the solution. This review will help to determine the current state of the company’s IT architecture, and identify the most suitable way to integrate with the TMS (see ‘Connectivity’ below) and construct a customer portal.

Conducting an IT review early on in the process can help to prevent delays or challenges during the implementation phase.

3. Connectivity

After determining the scope of the project and reviewing IT maturity, a key criterion will be the ability to connect the visibility solution to their existing IT ecosystem in general and their TMS provider in particular. Integration between these systems can be done using various methods to collect data such as EDI, API, or sending a flat file like an Excel spreadsheet.

The integration allows for a two-way flow of information between the TMS and the visibility solution. This will enable the TMS to send shipment information to the visibility solution, while the provider can track and trace the shipments and send back information such as shipment milestones, estimated time of arrival, and different events.

It is crucial that the integration is set up in a way that provides real-time visibility of the shipment’s location and status to optimize supply chain management.

“One of the big advantages of Wakeo is that, it has a high level of connectivity with our TMS CargoWise.” - said Lionel Tristan, Managing Director at Fracht France. “The two systems are communicating both ways.”