Webinar replay | Global Supply Chain Architecture: Examining Red Sea’s Evolving Impact - Watch Now

- Sector

Construction

- Scope

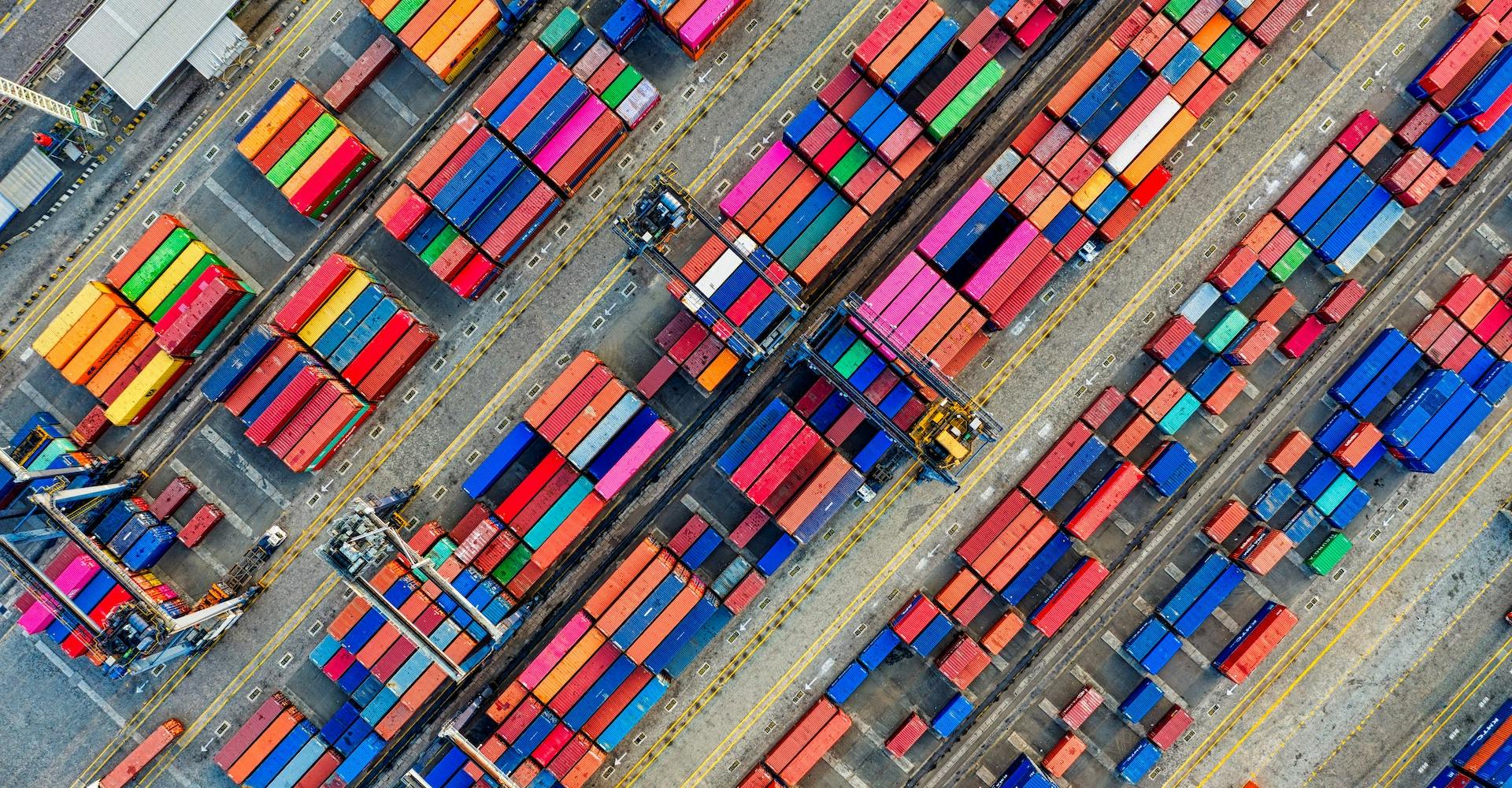

Sea port-to-port shipments

- Users

500+ users

How Hilti leverages neutral visibility data to optimize their supply chain

Hilti, a global leader in construction fastening and demolition technology, has been shaping the industry since 1941. Founded by the Hilti family in Schaan, Liechtenstein, Hilti boasts a truly global footprint, with over 34,000 employees in more than 120 countries. They prioritize direct customer relationships, averaging roughly 280,000 daily interactions with construction professionals. One of Hilti's unique strengths lies in its end-to-end supply chain management.

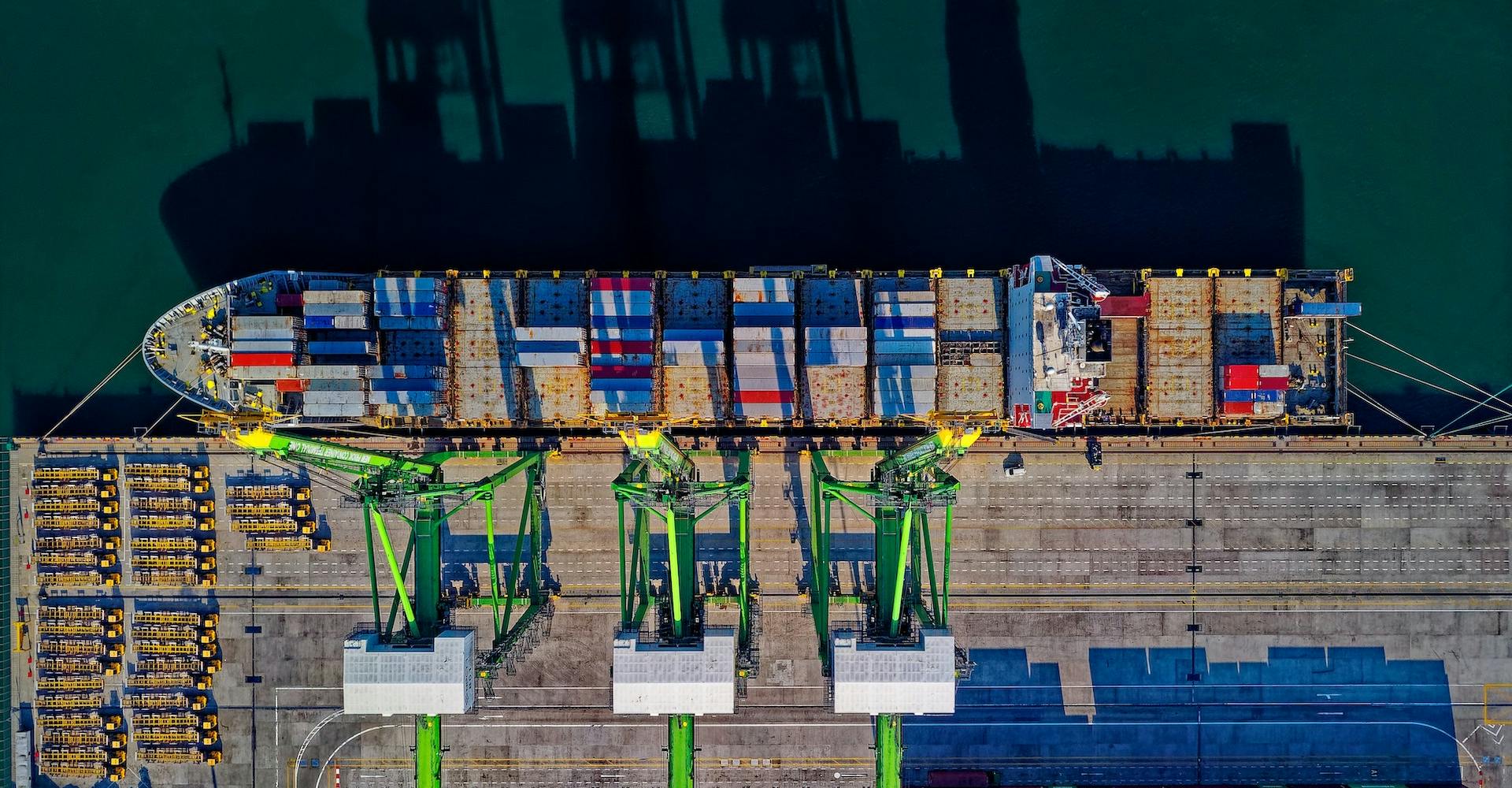

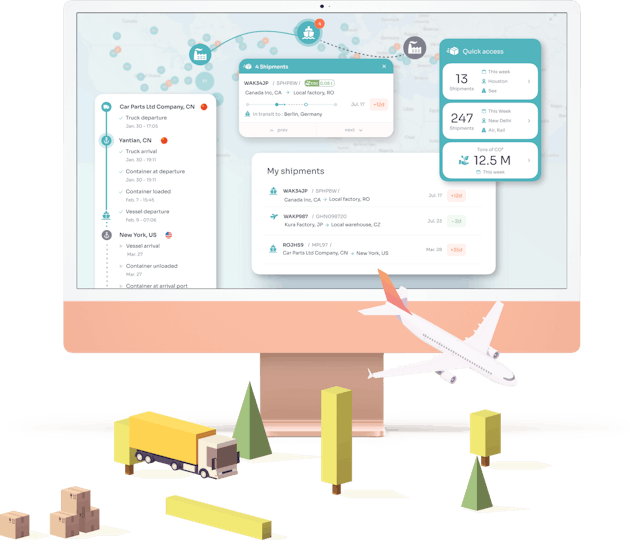

They manage the entire supply chain, from raw materials to customer delivery, including batteries, dangerous goods and overlength material. However, managing such a vast and complex supply chain requires innovative solutions. Wakeo's real-time visibility platform empowers Hilti to optimize their global logistics operations, ensuring construction projects receive the right tools, on time, and every time.

Customer centric

"We chose Wakeo for its customer centric approach, its coverage on sea freight and a good accuracy of ETA."

Richard Caron, Global Head of Transport & Warehousing at Hilti

- Lack of reliable information and low service level from service providers

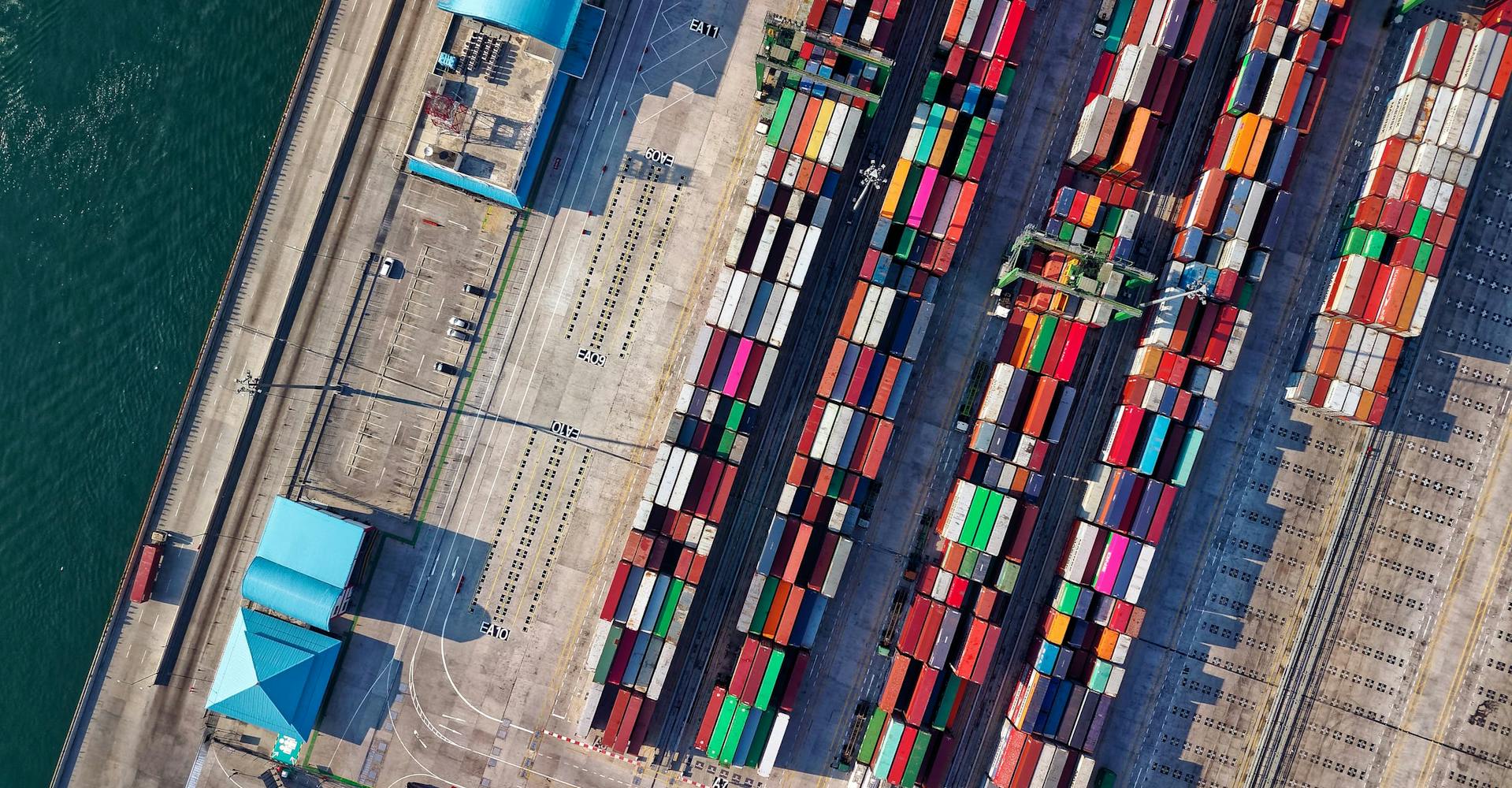

- Lack of visibility on unloaded containers and impacts on D&D costs

- Difficulties in getting accurate ETAs putting customer experience at risk and implying last minute air shipments

- Lack of neutral and independent data to evaluate service providers’ performance

- Get full visibility on intercontinental flows, especially on unloaded containers & reduce D&D costs

- Anticipate stock out situations and reduce lead time with outstanding predictive ETA

- Improve customer experience with tracking information & user-friendly platform

- Spread tracking information within HIlti’s IT systems and freight forwarder ecosystem

Our solution

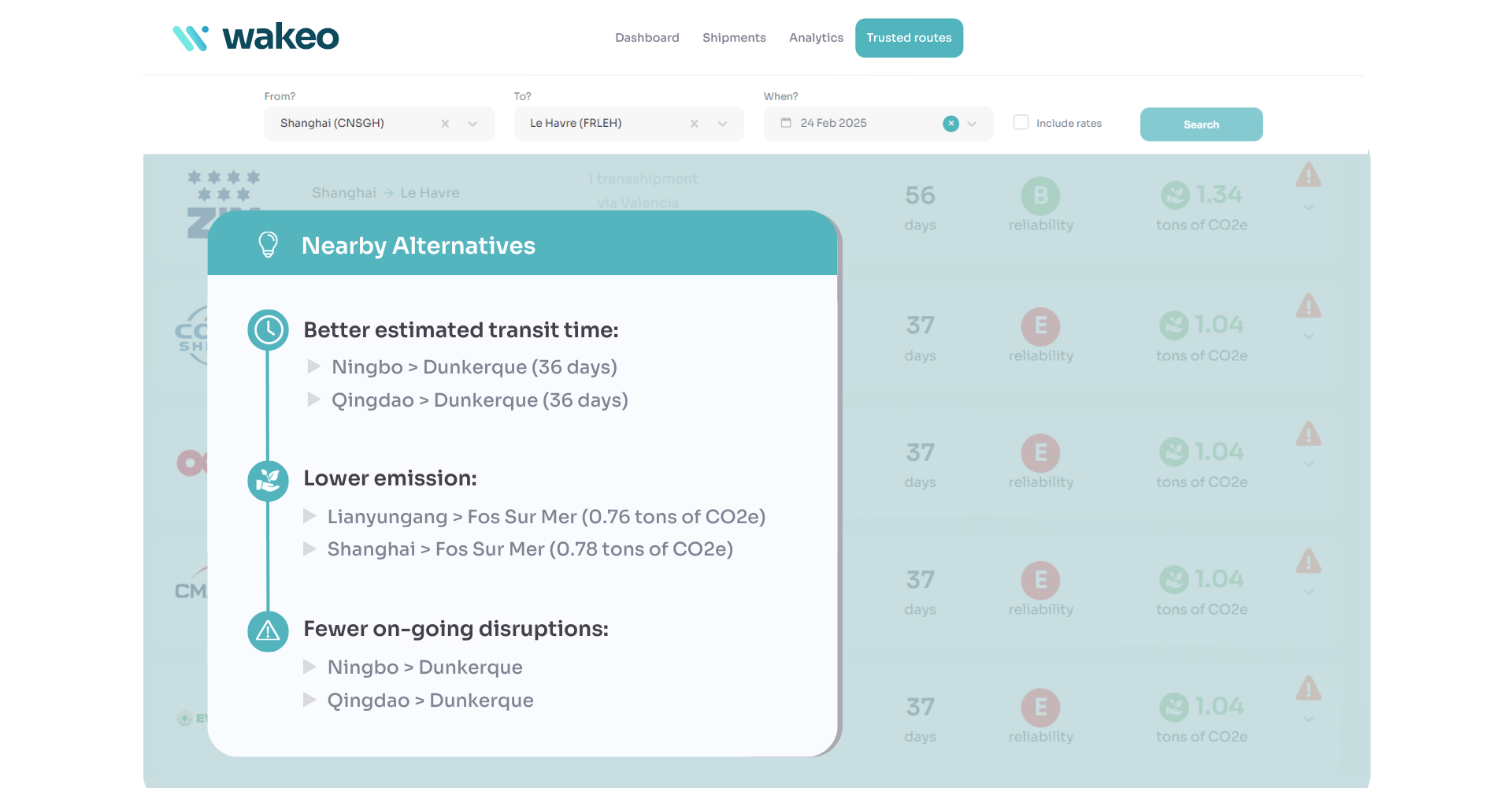

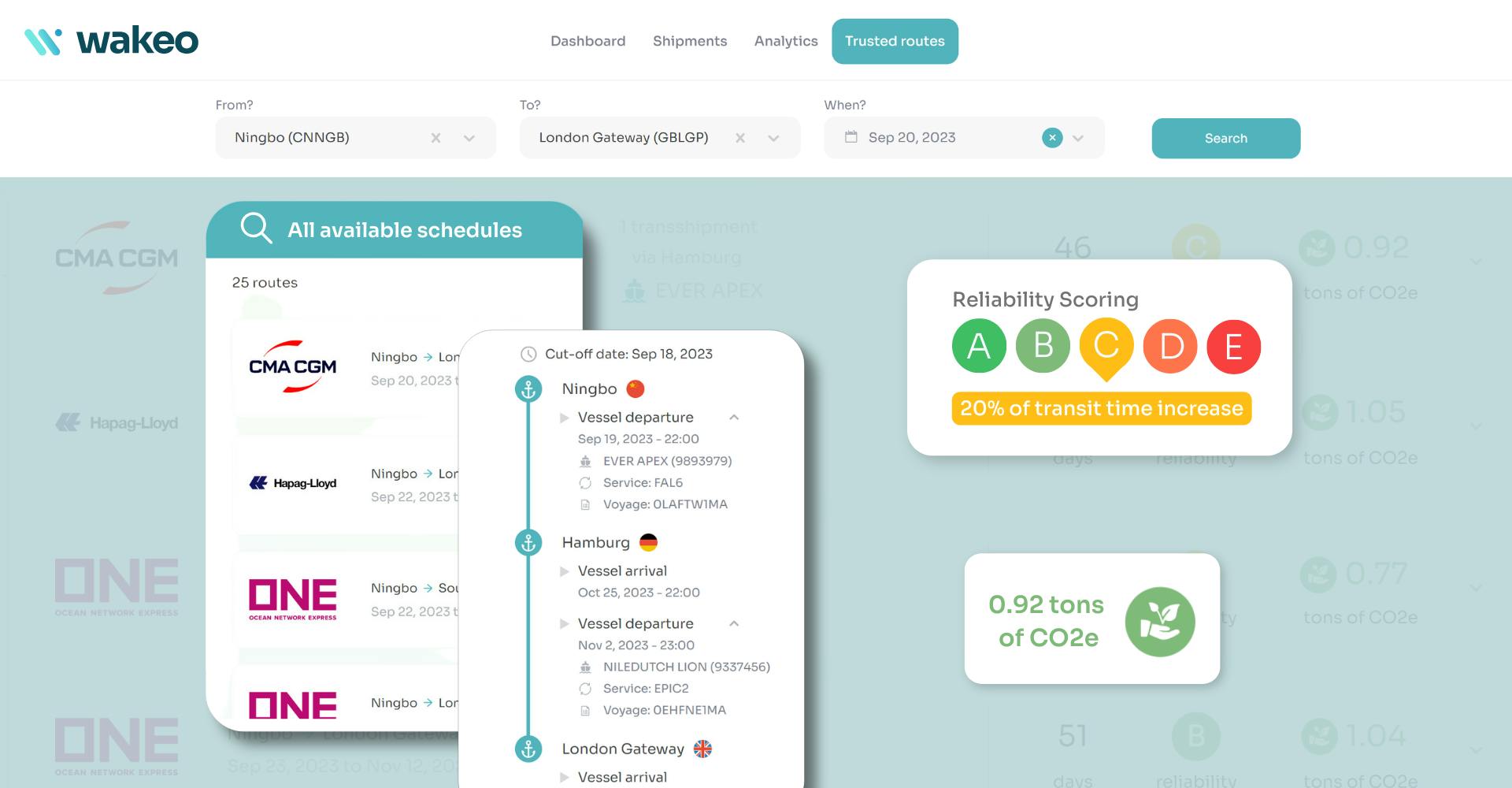

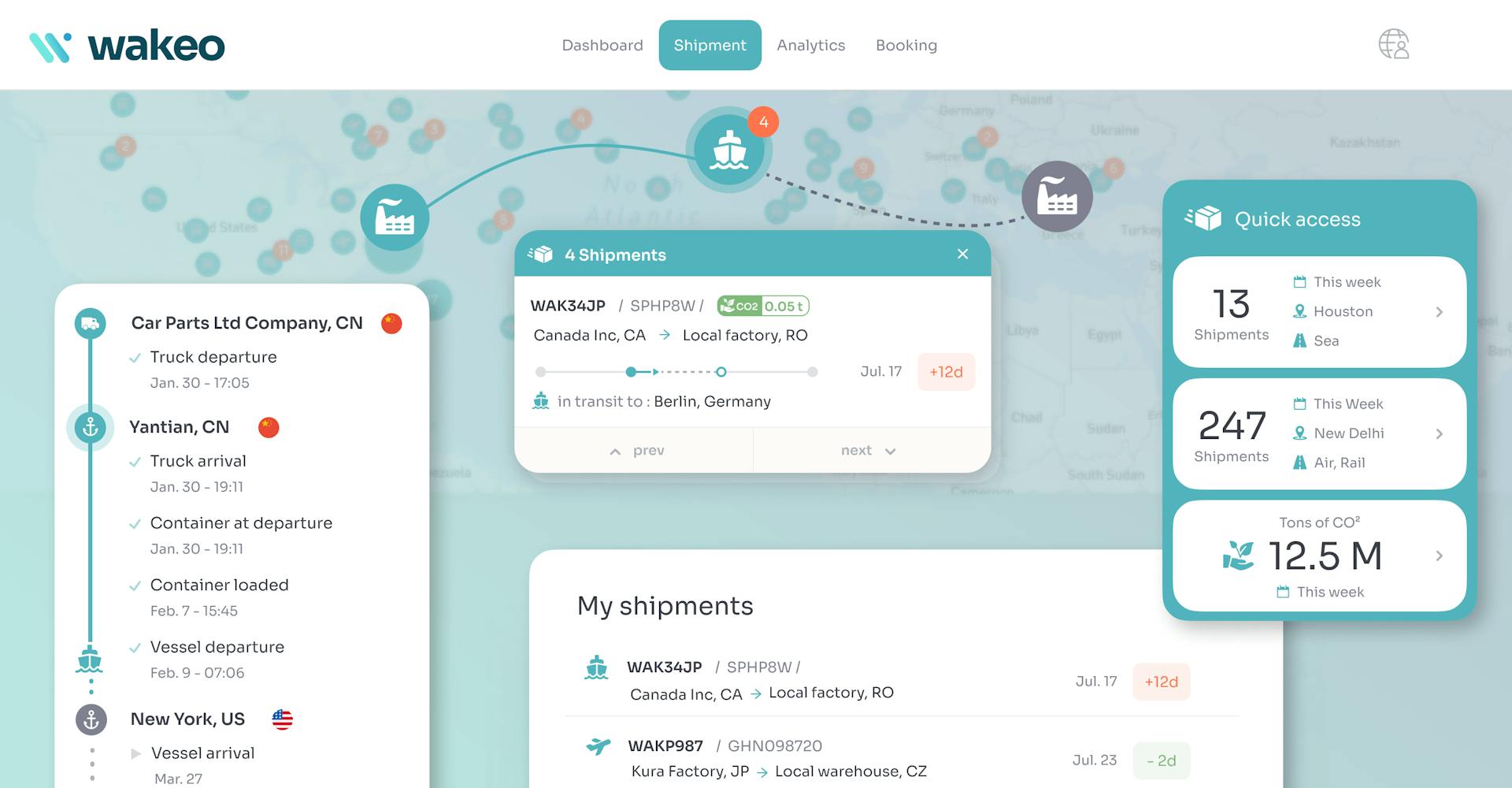

- All-in-one multimodal visibility platform including benchmark, CO2 calculations and alerting

- Predictive ETA information automatically shared throughout the company

- Built-in and customizable analytics with neutral & independent data to evaluate carriers’ performance

- Smooth integration with existing ERP - SAP to better monitor the inventory level

Return on investment

- 85% accuracy on ETA 10 days in advance resulting in a better anticipation of arrival dates

- Reduce lead times & decrease interest on stock by CA. 12%

- Reduce container handling charges and save up to 10% of workload

- Save 2-5% of airfreight cost

- Collaborate more efficiently with transport service providers, leading to better cost analysis and monitoring, including D&D and freight costs